25 Mar

Posted By

0 Comment(s)

1030 View(s)

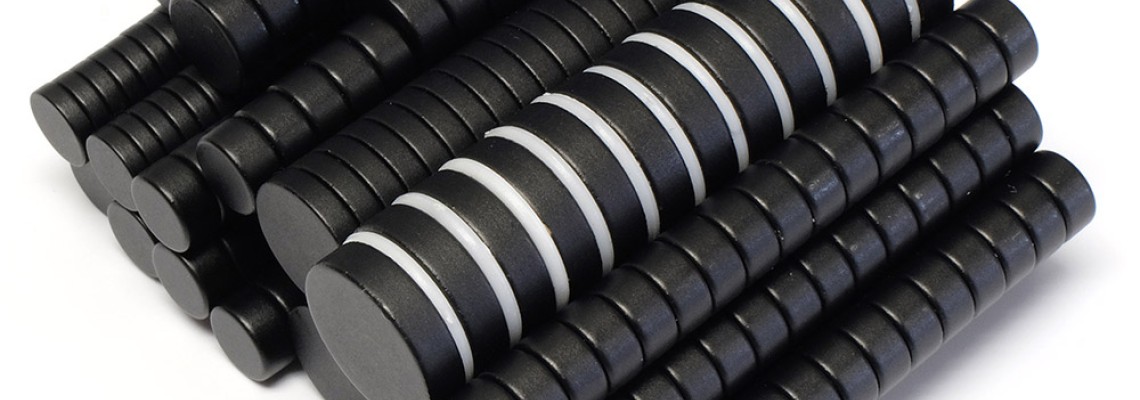

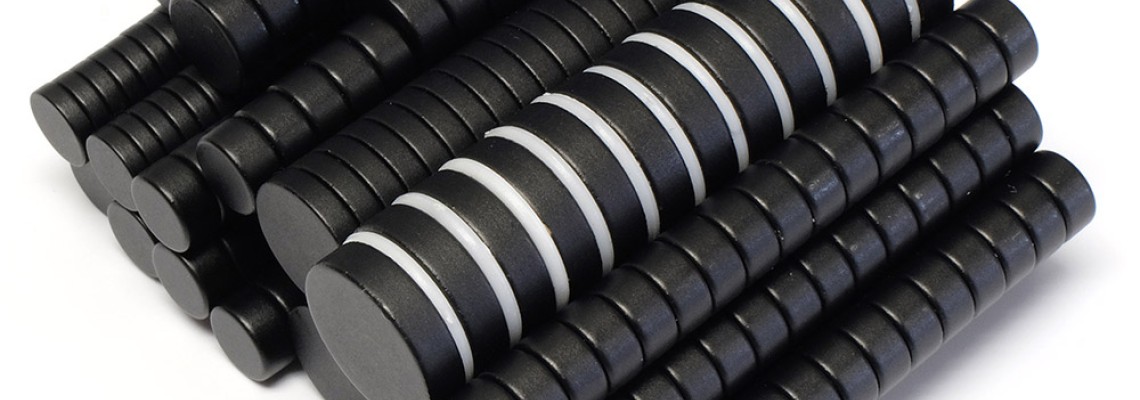

Epoxy-coated neodymium (Neo) magnets offer several advantages over uncoated or differently coated magnets. These advantages stem from the protective and functional properties of the epoxy coating, which enhances the durability, performance, and versatility of the magnet. Below are the key advantages:

1. Corrosion Resistance

- Neodymium magnets are highly susceptible to corrosion due to their composition, which includes iron and neodymium. Exposure to moisture, humidity, or harsh environments can lead to oxidation and degradation.

- Epoxy coating acts as a barrier, protecting the magnet from moisture, chemicals, and other corrosive elements. This significantly extends the lifespan of the magnet in humid or wet environments.

2. Enhanced Durability

- The epoxy layer provides a tough, protective shell that shields the magnet from physical damage, such as chipping, cracking, or abrasion.

- This makes epoxy-coated magnets more durable in applications where they may be exposed to mechanical stress or rough handling.

3. Electrical Insulation

- Epoxy coatings often provide a degree of electrical insulation, preventing the magnet from conducting electricity. This is particularly useful in applications where electrical interference or short circuits must be avoided.

4. Aesthetic Appeal

- Epoxy coatings can be applied in various colors (e.g., black, red, blue, etc.), giving the magnets a clean and professional appearance. This is beneficial for consumer-facing products or applications where visual appeal matters.

5. Chemical Resistance

- Epoxy coatings are resistant to many chemicals, including oils, solvents, and mild acids. This makes epoxy-coated Neo magnets suitable for use in industrial environments where exposure to chemicals is common.

6. Improved Adhesion

- The epoxy coating can enhance the ability of the magnet to bond with adhesives or other materials. This is particularly useful in applications where the magnet needs to be securely attached to a surface.

7. Versatility in Harsh Environments

- Epoxy-coated magnets are ideal for outdoor or marine applications, as well as in medical, automotive, and industrial settings where exposure to moisture, salt, or chemicals is likely.

- They are also suitable for high-humidity environments like bathrooms, kitchens, or laboratories.

8. Safe for Skin Contact

- Unlike nickel-plated magnets, epoxy-coated magnets reduce the risk of skin irritation, making them safer for wearable applications.

9. Customization Options

- Epoxy coatings can be tailored to meet specific requirements, such as thickness, texture, or color. This allows manufacturers to customize the magnet's properties for specialized applications.

10. Reduced Risk of Contamination

- In sensitive industries like food processing or medical devices, epoxy coatings prevent the magnet from shedding particles or corroding, reducing the risk of contamination.

Applications of Epoxy-Coated Neo Magnets

- Automotive: Sensors, actuators, and motors.

- Industrial: Machinery, conveyor systems, and magnetic separators.

- Marine: Boats, underwater equipment, and navigation systems.

- Medical: MRI machines, prosthetics, and diagnostic devices.

- Consumer Goods: Refrigerator magnets, jewelry, and crafts.

- Renewable Energy: Wind turbines and electric vehicle motors.